Compressed Air System Costs

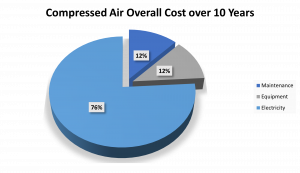

Most industrial facilities need some form of compressed air, and compressed air generation is often one of the most expensive sources of energy in a plant.

Enemy #1:

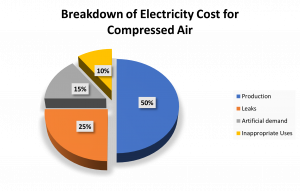

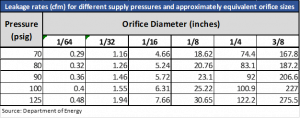

Leaks are a significant source of wasted energy in a compressed air system.

Facilities that do not have an active leak prevention program waste upwards of 40% of compressor output due to leaks.

Leaks Cause Major Problems:

- Fluctuating system pressure,

- Excess compressor capacity,

- Decreased service life,

- Increased maintenance costs, and

- Increased utility costs.

Compressed Air System Evaluation Services

UA SafeState’s team of environmental consultants provide onsite assessments and recommendations to improve air systems.

Applying best energy management practices can lead to significant savings in compressed air systems.

This low-cost scope of work includes:

- Utility bill review,

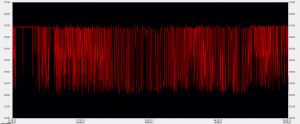

- Evaluation of system demand and load with ammeters,

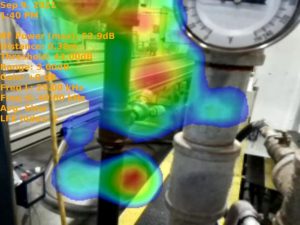

- Ultrasonic leak detection, and air leak tagging,

- Waste heat evaluation using a FLIR thermal imaging tool,

- Data analysis and assessment with Department of Energy AIRMaster + tool,

- Determination of compressed air needs (quantity and quality)

The system evaluations are compiled into a detailed report that includes recommendations and return on investment (ROI) information for all recommended activities.

By requesting a compressed air evaluation, facilities can reduce wasted energy, save money, and also lower their carbon footprint

Resources & Materials

Contact Us

Request a low-cost compressed air facility evaluation.

SafeStateEP@ua.edu or call 205-348-3967